AGVs for autonomous production

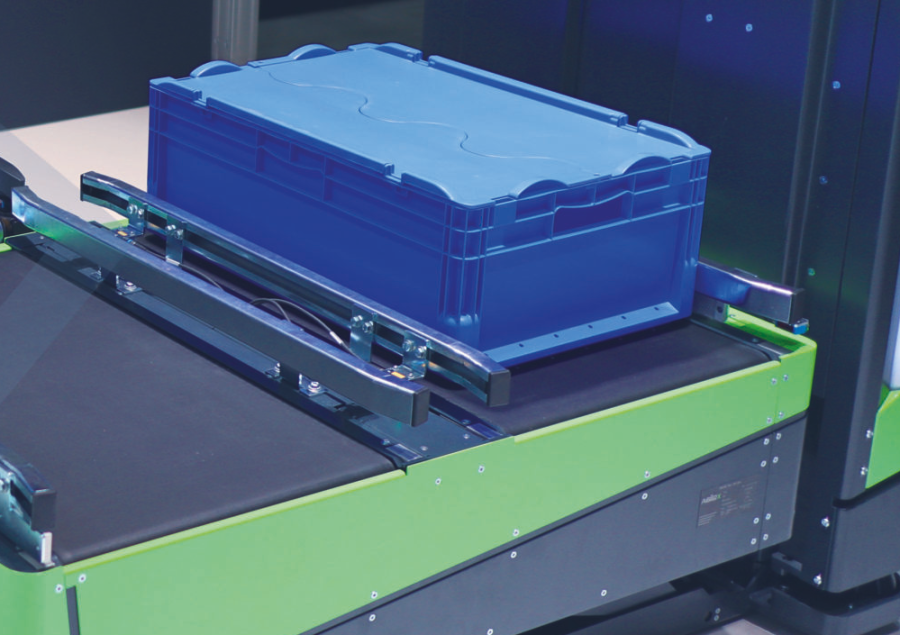

Intelligent automation cells with logistic robots permit autonomous production in metal cutting. PROMOT Automation offers comprehensive project support from design over layout planning to final acceptance. Quality and know-how are the basis for successful customer-oriented handling.

The PROMOT automation cells can be equipped with an AGV interface. With our in-house control software ProMASTER you can create and manage job orders and transmit them to the fleet management of the AGV transport systems. Here the individual manufacturing and process steps can be defined individually for each job order, from commissioning over various transport and handling sub-steps to multiple handling, washing, and measuring operations. In this process, the control system not only assumes AGV control but can also participate in robot and machine control. It also makes completely unmanned production possible.

Features

- Control of material flow, generation of transport jobs

- Easy integration and full scalability

- Administration of workpieces (article, assignment, machining status, site)

- Storage place administration upstream and downstream of the cell, as well as in defined locations

- Communication with AGV fleet management, independently of the manufacturer

- Flow control of automation cells and machining tools

- Unlimited mobility on a very small floor space

- Flexible process control

- Interface to MES, ERP, and CAD-/CAM systems

Benefits

Key Features

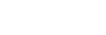

- Transport of load carriers

- Transport of basket stacks

Direct material flow connection with transfer of individual load carriers to automation cells. The load carriers are transferred individually from the AGV to standard roller or chain conveyors.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.