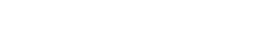

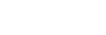

with flexible robot

Palmaster Setup-Master - maximum productivity

In robot cells or linear robot systems, the additional Setup-Master function provides for the automated setup of small or series parts directly into the machine. This means that two tasks can be solved with one system – the automated production of small, pallet-bound batches and the automated clamping of series parts.

Features

- Suitable for cubic and cylindrical blanks

- Storage of blanks in matrix pallets for high buffering effect

- Gripper station for various component grippers

- Different clamping fixtures can be stored in the shelving system

- Suitable for machines with or without pallet changer

- ProSYS host computer software for optimised order control

Benefits

Setup-Master - Modules

- Matrix pallets

- Interchangeable part gripper

- Gripper station

- ProSYS host computer software

The raw, semi-finished and finished parts are stored on matrix pallets. The setup station is used as the central operator interface. Several different production orders can also be processed on one matrix pallet. The shelf capacity can be filled with any number of matrix pallets – this creates a high storage capacity and flexibility in production.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.