Stacking cell

to your project

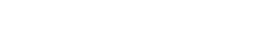

PROMOT stacking cell- available as a standard module in the modular system in various standard sizes

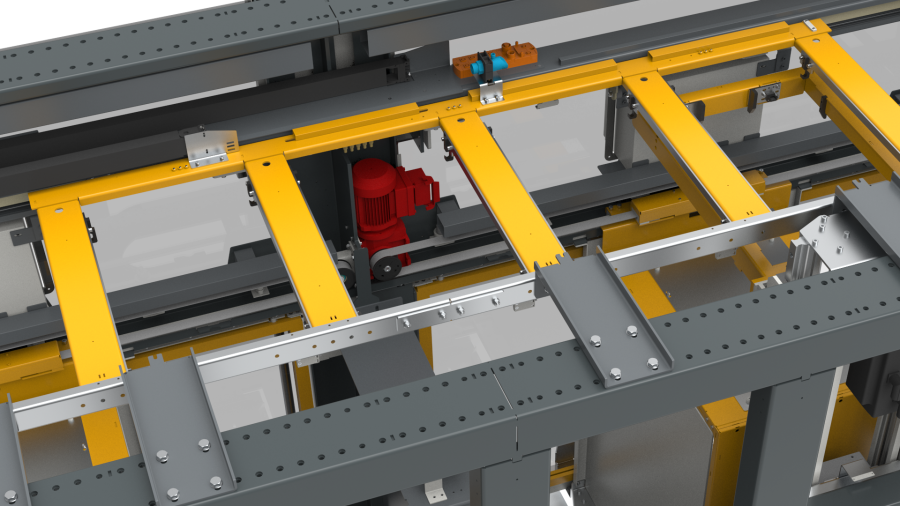

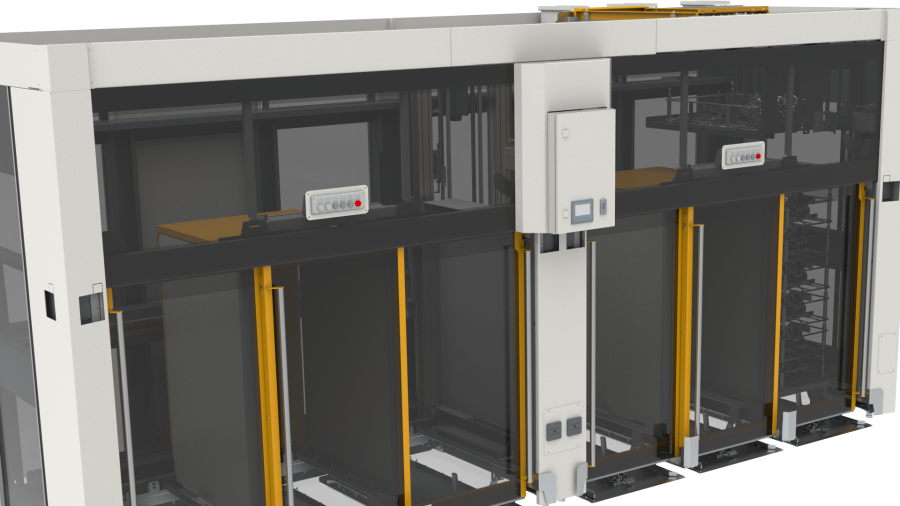

No task is quite like another. As a modular system, the PROMOT Cellmaster CM can be adapted to meet any requirements. In addition to expansion modules for additional cells, various basket provisioning options are also available. Using a decoupling module makes it possible, for example, to change baskets during operation without creating any waiting time for the loading system. The modularity is not limited to the mechanics – the Cellmaster will adapt to your existing logistics systems with standardized software processes.

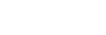

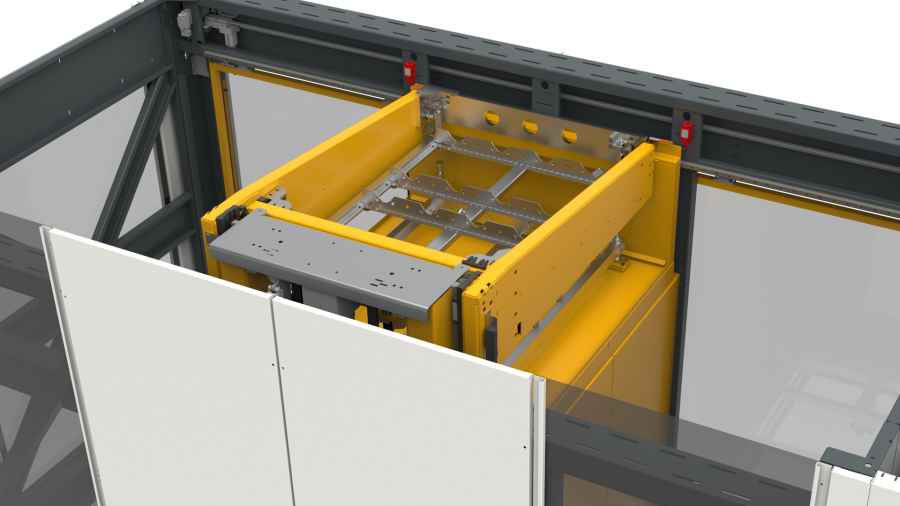

The basic module is equipped with 3 chambers which are directly accessible through sliding doors. This allows you to react quickly to production changes without having to wait for the entire stack to be restacked each time. Remove semi-finished stacks, load a new stock stack and done! Each finished part chamber is sealed off by a slide guard, so the stacks can be changed without interrupting the production process.

The respective finished part chamber is always sealed off by a sliding guard so that the stacks can be changed without interrupting the production process.

The following standardized software sequences are possible:

- Standard sequence

- Standard sequence with basket on the sliding guard for filling and emptying operations

- Gap collection in the topmost basket

- Single basket sequence

- Single stack sequence

Benefits

400 x 600 mm

600 x 800 mm

800 x 1,200 mm

Typical applications

- Standard stacking cell 600x400mm

- 6-fold stacking cell for 2 part types

- Decoupling module for material flow chains

- Stacking cell for pallets 1,200 x 800 mm

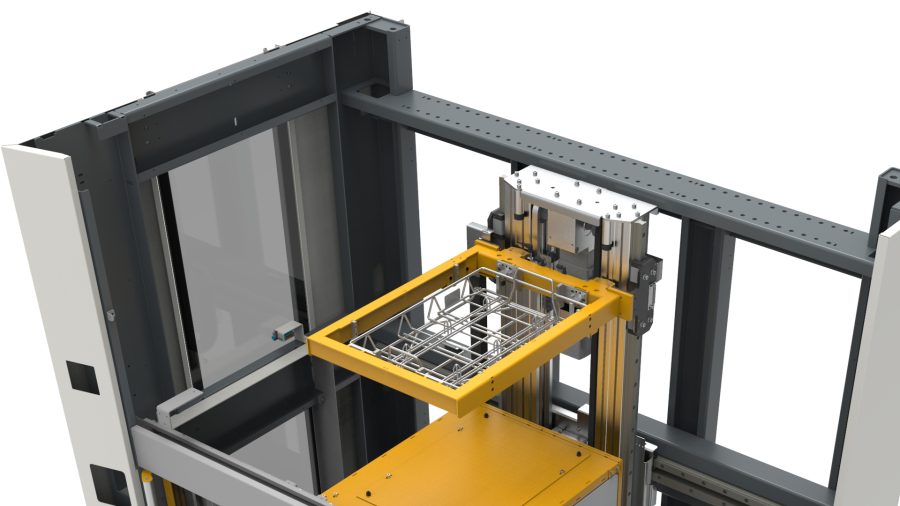

Standard stacking cell for 600 x 400 mm mesh baskets with 3 chambers. The movable sliding guard enables uninterrupted operation without downtime when changing stacks.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.