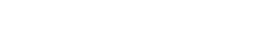

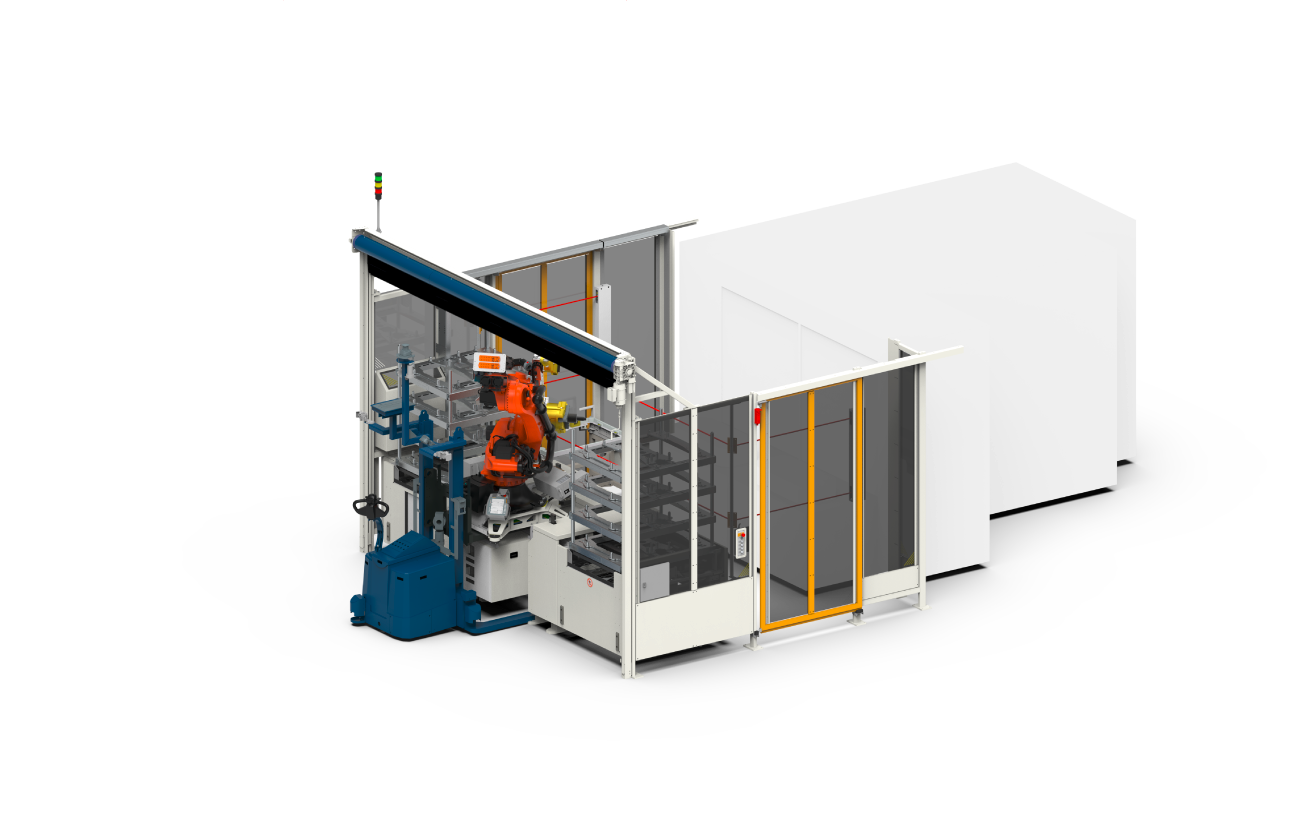

Operating several processing machines with just one robot

The mobile robot solution combines the flexibility of a robot with the mobility of an Automated Guided Vehicle (AGV) or an Autonomous Mobile Robot (AMR) to revolutionise manufacturing processes. Thanks to the modular system, the PROMOT Mobile Robot offers countless combination options for manufacturing different parts with the same equipment. Whether in the automotive industry, aerospace, or mechanical engineering – the PROMOT Mobile Robot adapts flexibly to production requirements.

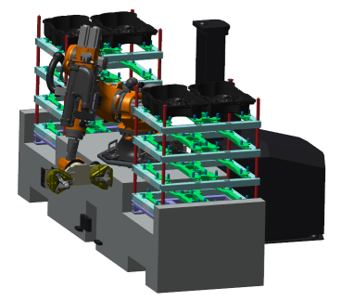

Patented version for longer processing times

The AMR safely navigates the robot to various stations. The patented detachable design allows the robot to perform its tasks in one station while the AMR simultaneously takes over other tasks such as material transport. For longer processing times, this is the optimal solution for efficiently utilising the capacities of the robot and the AGV. By carrying out tasks in parallel, productivity can be significantly increased and downtimes minimised. The flexible and independent usability of the AMR also improves the overall equipment effectiveness (OEE), which leads to increased profitability.

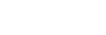

Version for a smaller range of parts and medium processing cycles

Alternatively, the AGV can be permanently connected to the robot. This variant is particularly suitable for smaller parts and medium processing cycles, as the AGV does not take on any additional tasks. Especially when different processing cycles and flexible adaptation to various workpiece types are required, the permanently connected AGV-robot variant is ideal.

Features

- Implementation is independent of the AMR and robot manufacturer

- Cobot or industrial robots can be used

- AMR can be used for robot tools and material transport

- Flexible production routes and process flows possible

- Machine connection with automated NC programme transfer and selection

- Quick integration of additional processing stations possible

- Easy scalability of the system with additional robots or AMRs

- Precise positioning of the robot in the respective processing station

- ProMASTER as control software

Benefits

Patented Mobile Robot Solution

- Mobile Robot

- Docking Station

- Automation and Safety Hand in Hand

- Smarte Software

The main task of the mobile robot is to make the production and handling of workpieces more economical and to realise an easily scalable production system. A key aspect is the ability to transport the robot flexibly between different processing stations so that a separate robot is not required at each station.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.