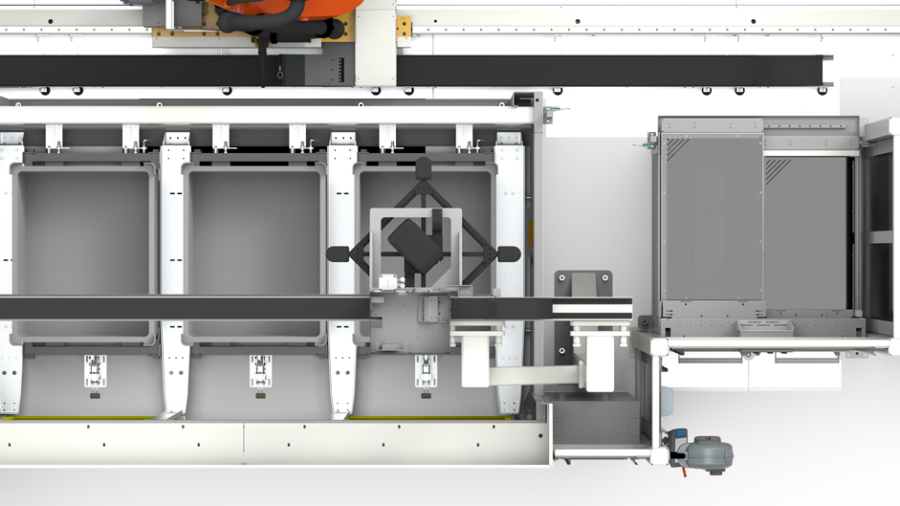

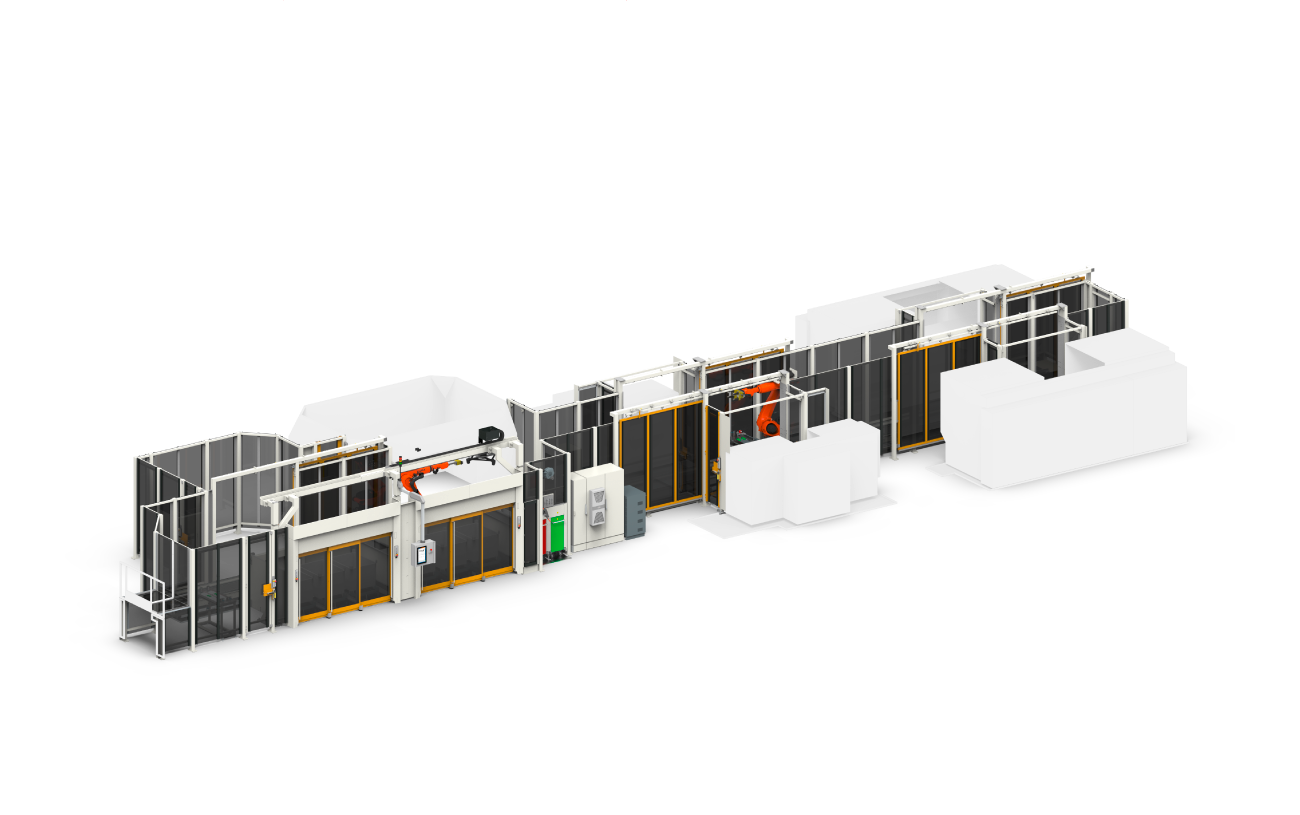

Random bin picking

Automated parts picking

With PROMOT automation solutions, you can master the automated removal of parts from containers and increase the efficiency of your production processes. Our proven robot systems form the basis for complex image processing, collision-free parts removal and intelligent robot control.

Features

- 2D object detection for single-level storage detection

- 2.5D object detection for stacked parts with automated height detection

- 3D object recognition for bulk goods

- Collision-free parts removal

- Intelligent robot control

- Adaptable gripper technology

- Modular design

- Can be integrated into existing production lines

- User-friendly software & user interface

Benefits

CUSTOMISED SOLUTIONS

With the modules of the PROMOT modular system, we realise the optimum solution for you.

CONSULTING

Consultancy and design development are carried out for the manufacturing processes. PROMOT selects the optimum camera system to match the production and logistics process.

Test trials with real components are possible at any time!

SOFTWARE & HARDWARE

Reduction of the number of interfaces and overall complexity of the system.

INDEPENDENT DESIGN

Our solutions are independent of the machine manufacturer and have individual customised interfaces.

PRODUCTIVITY

Increased productivity through unmanned production and decoupling of man and machine.

OPTIMUM SIZE

Space-saving solution compared to conventional magazine modules.

Project examples

- Motor factory

- Connecting rod production

Motor factory

A leading manufacturer of drive systems integrated the PROMOT bin-picking solution for automated raw part feeding into its production line. This increased efficiency and significantly reduced labour costs in this area.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

Whether you have questions concerning mechanics, software or operation of your robot system,

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.

OVER 40 YEARS OF EXPERIENCE IN THE AUTOMATION OF MACHINE TOOLS