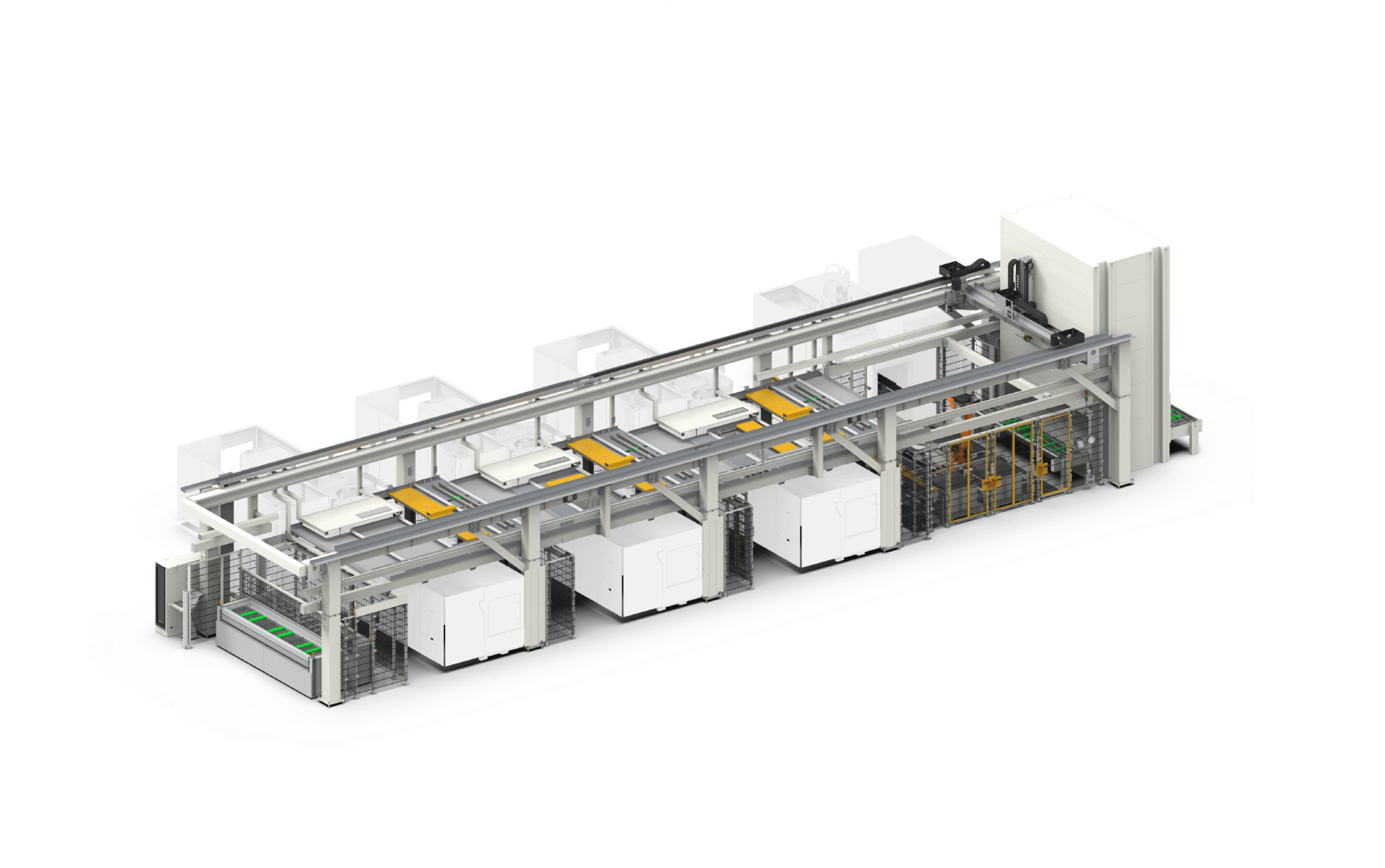

Flexible manufacturing of batch size 1 in workpiece handling

The flexible unmanned manufacturing of parts can also be implemented in workpiece handling. Thanks to a comprehensive plant concept, different machining processes are possible even in case of components with variable lengths and diameters.

The key elements are flexible gripper units, well-conceived component loading and perfectly coordinated interfaces. The intelligent plant software provides for smooth processes and seamless lot changes in manned or unmanned production.

Features

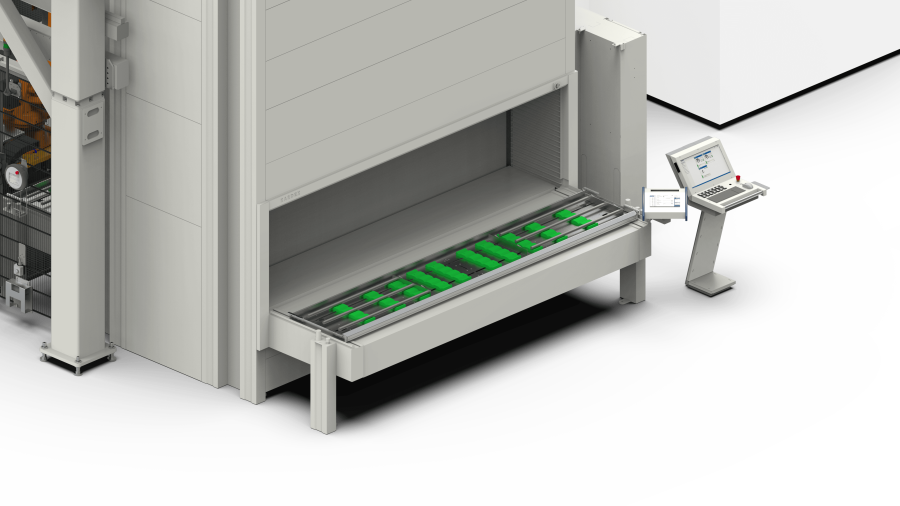

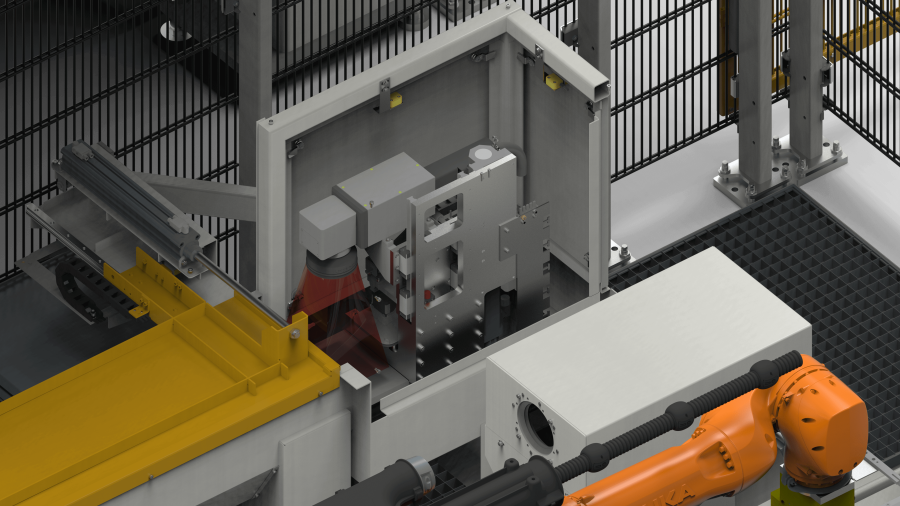

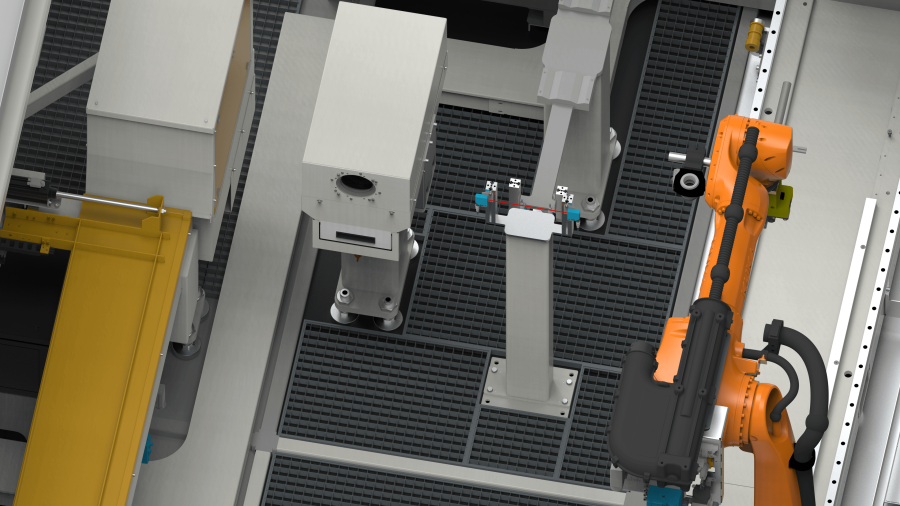

- Combination of robots and linear gantry

- Different machines in one system

- Automatic gripper change for different part sizes

- Mixed storage of raw and finished parts

- Serialisation of finished parts

- Component labelling with laser

- ProFLEX master computer software for optimised job control

- ERP / MES interface for optimised data flow

Benefits

Key Features

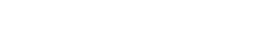

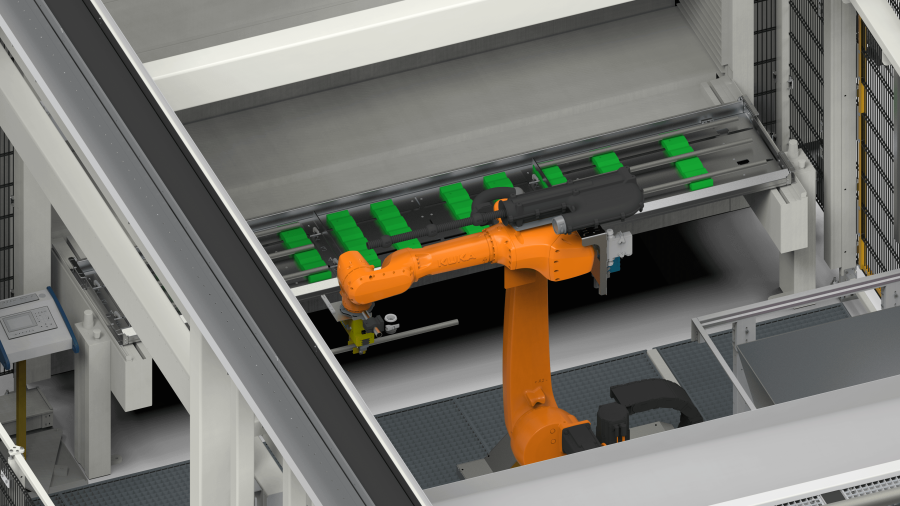

- Component loading with storage tower

- Laser labelling

- Flying workpiece measurement

- Automatic gripper change

To loading stations allow for decoupled component feeding. The loading of the shelf boards can be configured in different ways and can also be adapted to the production plan during ongoing operation. By means of the QR code, each nest is uniquely identified. Finished parts can also be removed by means of a level cycling device.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.