Automated machining of workpieces

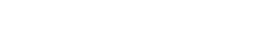

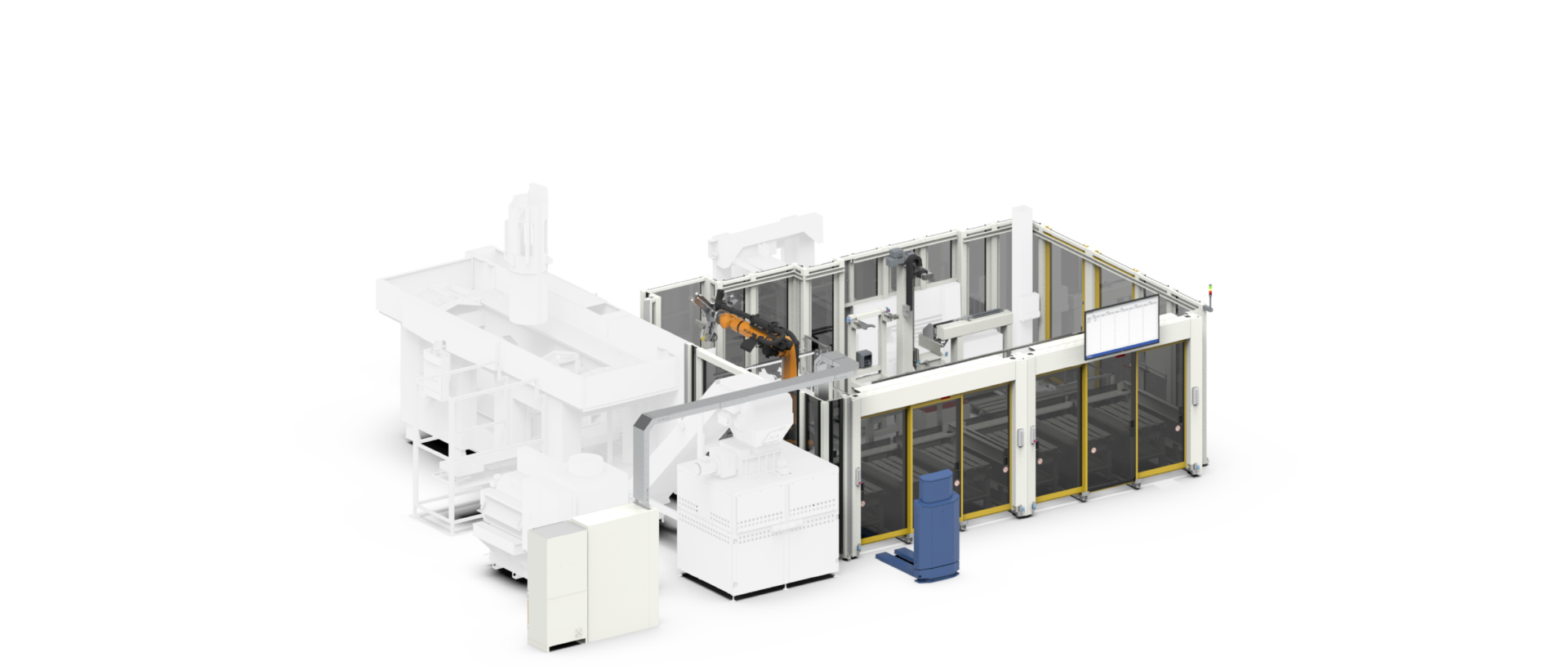

The automation solution from PROMOT Automation enables highly efficient processing of workpieces without complex retooling, even for small batch sizes. By using automated processes and flexible handling systems, workpieces with a wide range of geometries and specifications can be processed without time-consuming set-up processes.

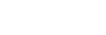

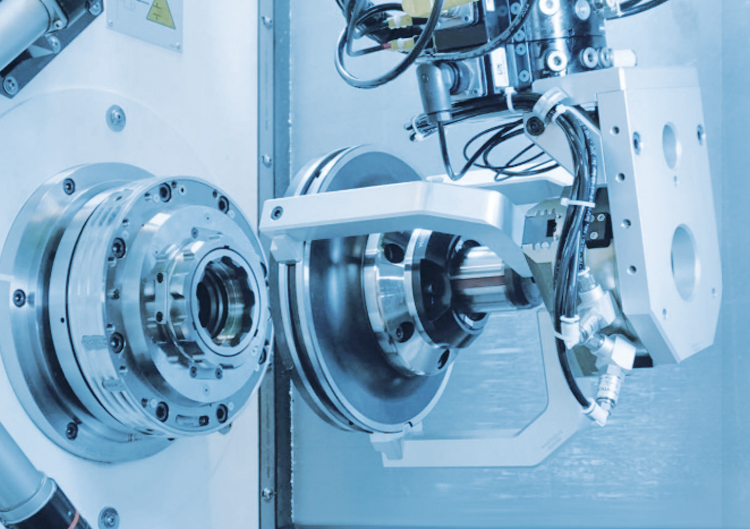

Automation enables the precise and efficient production of individual workpieces within a specific weight range. The use of servo grippers, as well as automatic gripper or gripper finger changes, allows the setup-free handling of a wide range of workpieces.

Additionally, the automation system handles the tooling of the machining equipment. With change options for clamping jaws, mandrels or collets, set-up processes on the machine are no longer necessary, further increasing productivity.

Features

- Seamless adaptation to different workpiece sizes

- Setup-free gripping

- All change parts are stored and managed in the automation system

- Automated clamping device change in the processing machine

- Optional integration into ERP systems and order control systems

- PROMOT software optimises the number of automatic retooling processes

Benefits

Automated or semi-automated workpiece changeover

- Gripper Change

- Clamping Jaws

- Collets

- Gripper Finger Change

A gripper change enables the gripper or its components to be replaced quickly and easily in order to adapt the functionality of the robot. This can be done automatically or semi-automatically to minimise downtimes. The purpose is to increase flexibility and efficiency in production by allowing different workpieces to be processed without manual intervention.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.