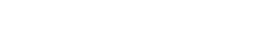

Hybrid automation

The entire PROMOT know-how perfectly applied

Special requirements call for special concepts, especially when complex requirements such as logistics tasks, general conditions or short cycle times come together.

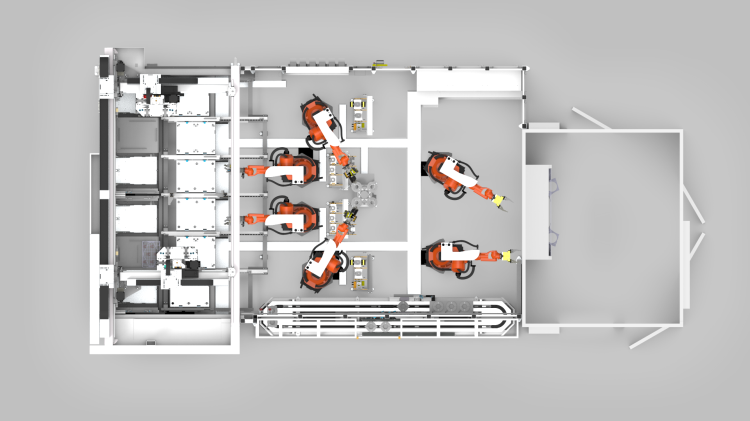

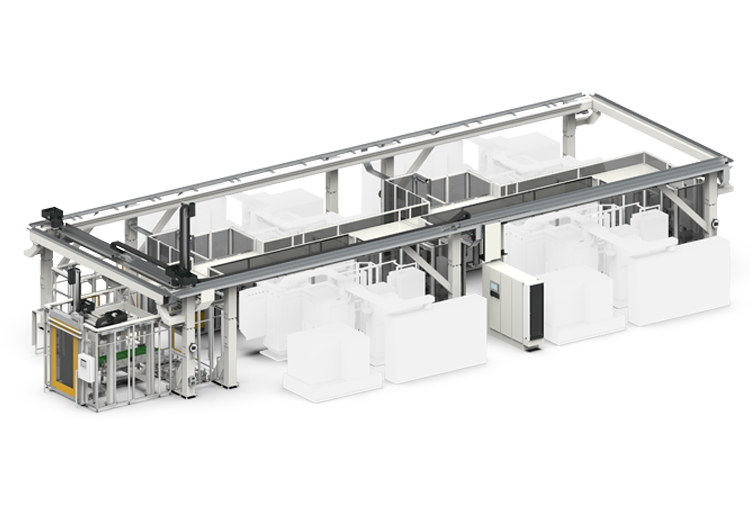

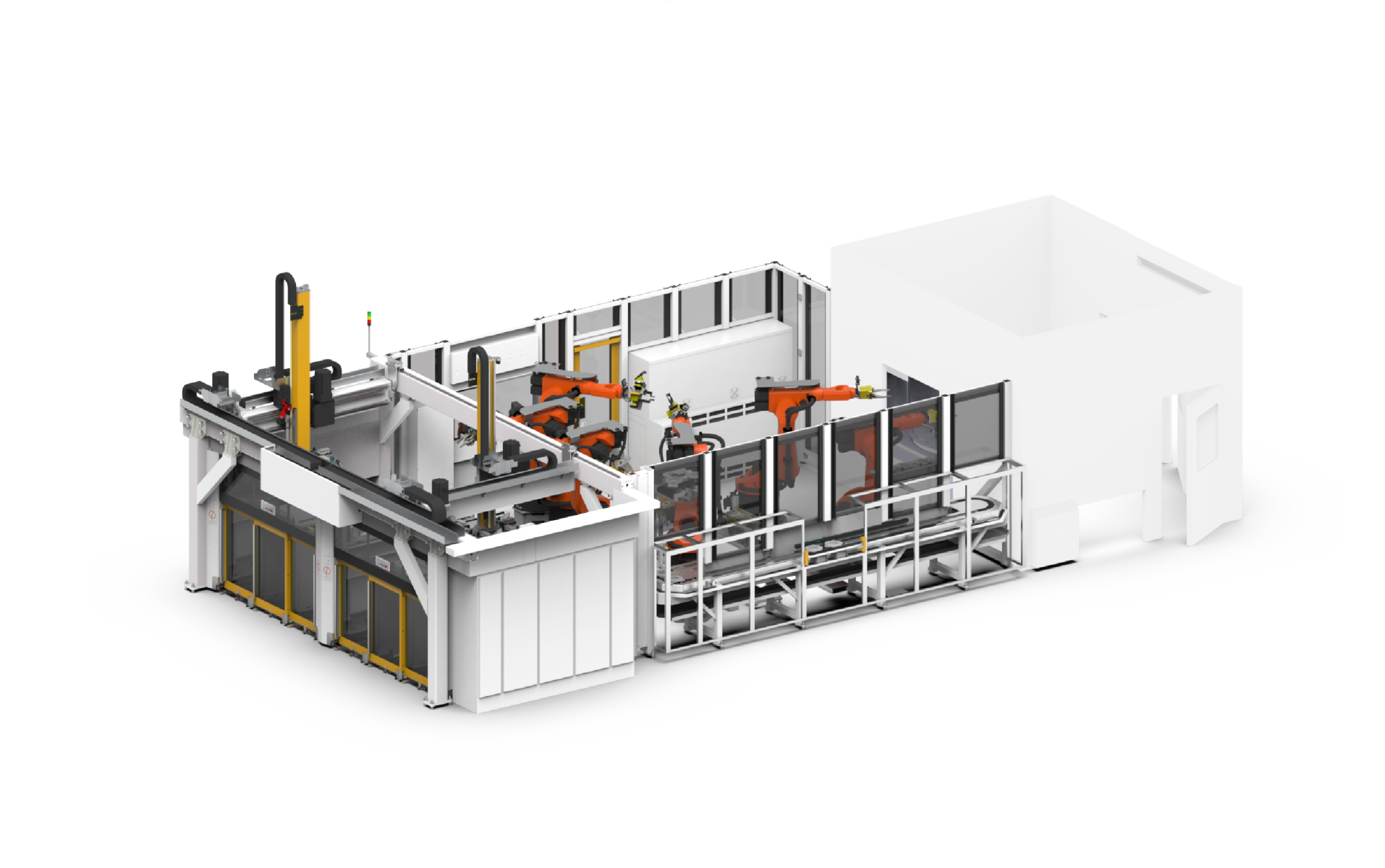

By utilizing the complete PROMOT modular system, we can combine several automation systems and implement advanced system concepts that meet diverse and demanding customer requirements.

The software solutions developed in-house optimize the processes within the system and thus make a significant contribution to maximizing productivity. We thus offer innovative solutions that are not only efficient but also extremely flexible and customer-oriented.

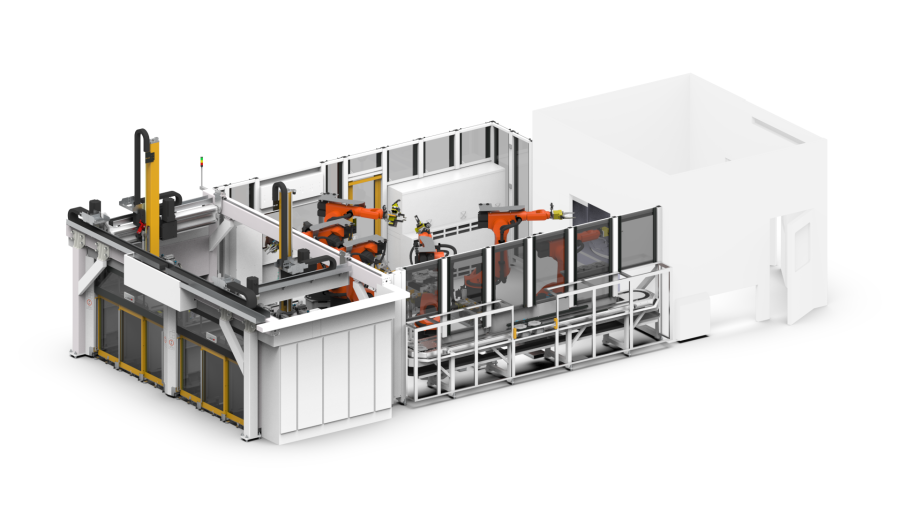

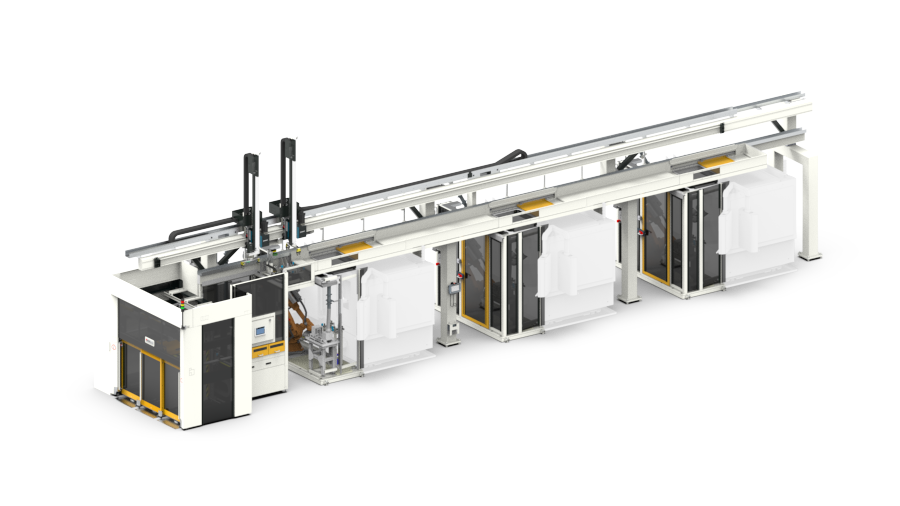

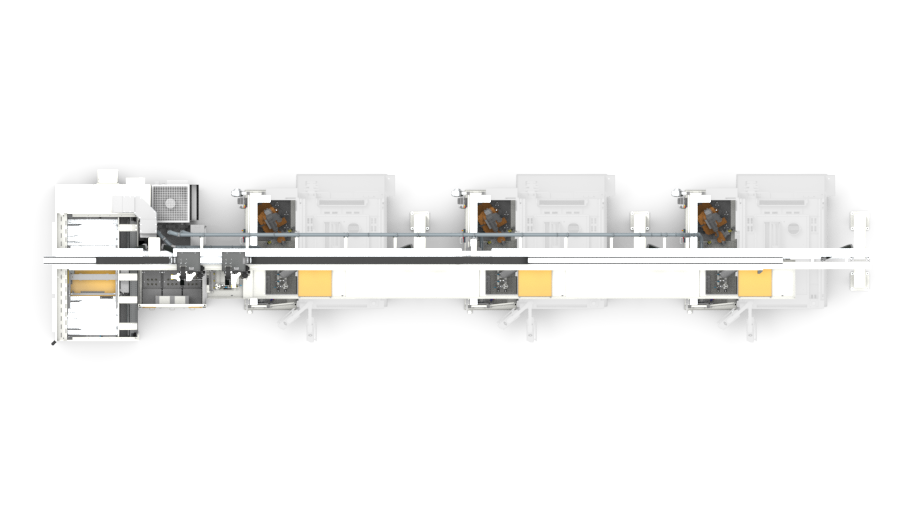

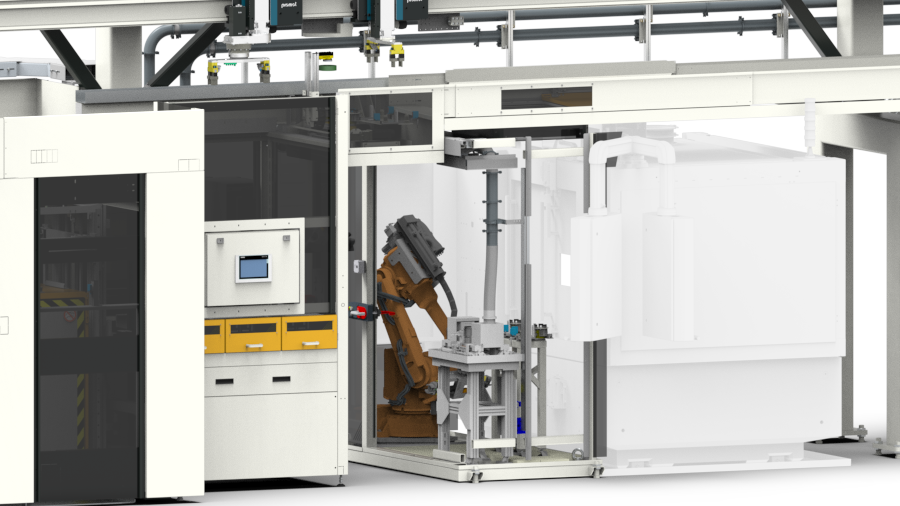

Gantries can reach longer distances in less time and save valuable floor space thanks to the gantry design. The robot can cover more flexible movement sequences over short distances and with different degrees of freedom. This combination allows an optimal production concept to be realized.

Features

- Combination of robot and linear gantry

- Only one operating unit for the entire automation system

- One central system control for the automation system

- Optimization of resource utilization

- SPC and NIO strategy can be designed variably

- Integration of manual workstations

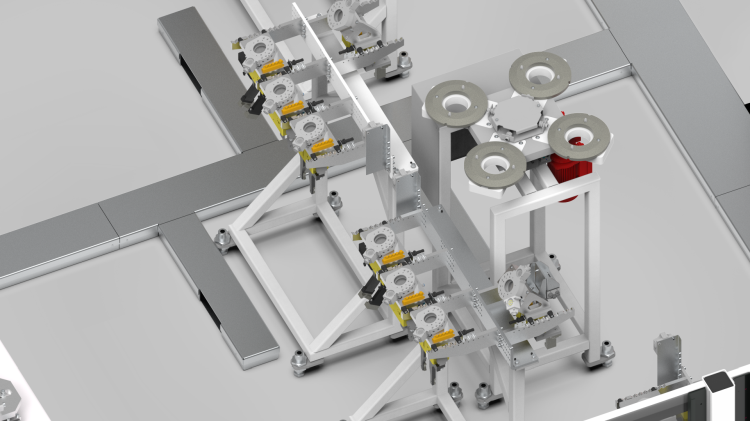

- Different workpiece magazines can be integrated (e.g. Cellmaster stacking cell, bulk material grid boxes, etc.)

Benefits

Examples of projects

- Short cycle times and pairing

- Interlinking of 3 machines

- From bulk goods to finished parts

Loading of the (unpaired) parts via basket stacks, separation of the baskets with gantry, loading of the workpiece trays, loading of the workpiece trays into the machine, set-up of the workpiece trays parallel to production time and removal of the now paired parts – and all this with a cycle time of 3 seconds.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.