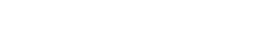

Fully automated parts handling from the raw part to the finished part

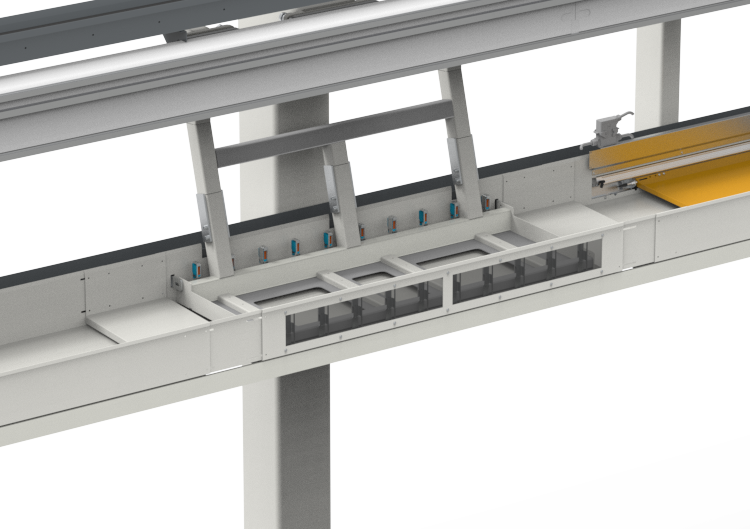

Portal interlinking is a proven concept for linking numerous processing machines in large-scale production. Many different automation solutions can be implemented with the modules from the PROMOT modular system.

Comprehensive sequence strategies, buffer concepts and emergency concepts for intermediate buffers as well as setup-free, on-the-fly type changeover of the system can be implemented to ensure that processes remain flexible and downtimes are avoided despite rigid interlinking.

Optional part tracking at component level ensures seamless quality documentation. With flexible buffer concepts, individual work sequences or sections can be automatically decoupled and coupled depending on the system status. This enables maximum OEE to be achieved with maximum output.

Features

- Standardised automation solution from the raw part to the finished part

- Interlinking of numerous processing operations

- Use of standard modules increases availability

- Reduced workpiece changeover times

- Improved flexibility thanks to additional gantry axes

- Flexible buffer cells for decoupling individual processing sections

- Integration of process applications, e.g. part marking, part tracking with serial numbers, etc.

- SPC and NIO strategy can be designed variably

- Integration of manual workstations

- Reduction of circulating stocks through optimized design of intermediate buffers

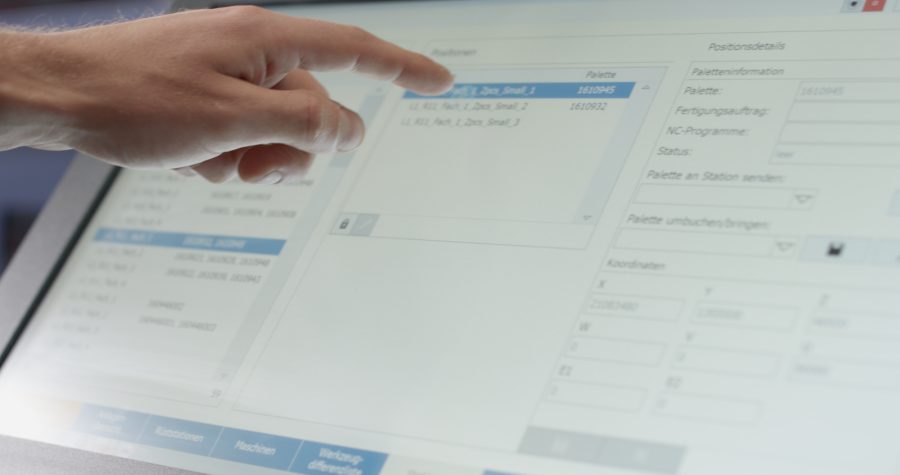

to customer-side production

control software

Benefits

Highlights

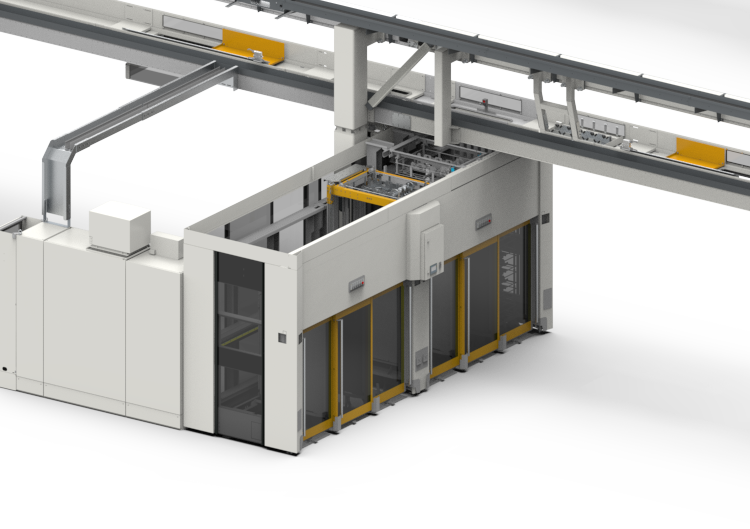

- High-performance gantry systems

- Flexible buffer concept

- Intelligent software solution

- Integration of manual workstations

Gantries with optimised acceleration and speed parameters are used for efficient parts transport. A specially developed drive and media supply concept enables maximum performance. The gantries can be designed as H-loaders or I-loaders, depending on the requirements of the respective processing machine.

SERVICE & SUPPORT

- Hotline

- Service

- Spare parts

- Modification & Retrofit

our hotline is there for you with our competent and experienced staff ready to handle all your concerns.